What issues should we pay attention to when customizing AGV batteries? For agv manufacturers, here we can start from the following aspects:

First, the battery

The battery cell directly determines the quality of our AGV battery, so we need to be cautious when choosing a battery cell.

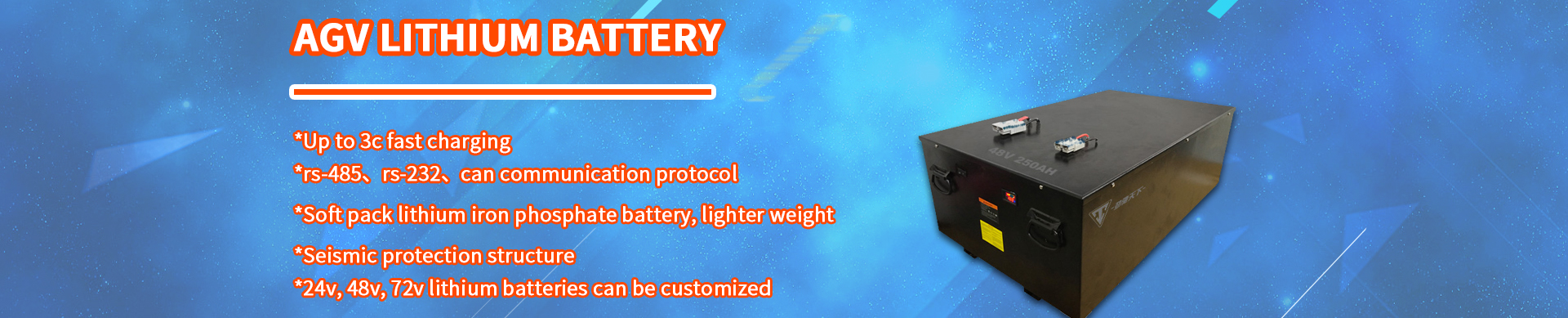

1. Safety: If the capacity of the battery pack is greater than 2400Wh, from a safety point of view, it is recommended to use lithium iron phosphate batteries. A ternary lithium battery can be considered for a battery with a small capacity, because a ternary lithium battery with the same capacity has a lighter weight. Of course, iron-lithium batteries can also be used for small capacity.

2. Cost: From the perspective of cost, the advantage of ternary lithium battery is a little bit bigger.

3. Working environment temperature: low-temperature charging and discharging performance of lithium iron phosphate battery is worse than that of ternary lithium battery. So this is also because we need to consider. However, the iron-lithium battery can be added to the pre-potential system, so that there is no low temperature difference, but the cost is a lot.

4. Weight: the order of weight from low to heavy: lead-acid battery, ternary lithium battery, soft-packed lithium iron phosphate battery, aluminum-shell lithium iron phosphate battery.

5. Charging current size: fast charging batteries can be selected for higher time requirements.

Second, BMS management system

If there is no communication protocol requirement, you can choose the hardware lithium battery protection board. If there are communication protocols such as RS485, 232, CAN, etc., you need to choose a stable and mature BMS management system, otherwise the failure will continue.

Third, the assembly process

Agv battery manufacturers are required to have relevant mature assembly experience and supporting production equipment.

Jinchi Technology specializes in providing AGV lithium battery solutions and has served hundreds of AGV manufacturers.

----Bring your dreams closer!

----Bring your dreams closer!